Anthology Batik Factory Tours in Bali, Indonesia November 2013

Peter Cho, Founder and Owner of Anthology Fabrics sharing his background with us and telling us how and why he started Anthology Fabrics.

To his right is Ketut, the owner of the factories that produce the Anthology Batiks. We are at the factory in Singaraja, which is the largest city in North Bali.

Batiks being stamped at the factory in Singaraja.

Blocks of rubber tree wax that will be melted and used for stamping the batiks at the Singaraja factory.

Melted rubber tree wax being used in the stamping process at the Singaraja factory.

Gorgeous stamp at the Singaraja factory.

Stamp and fabric awaiting stamping at the Singaraja factory.

Another stamp and fabric awaiting stamping at the Singaraja factory.

Helen, myself, Connie and Pat at the Singaraja factory learning how to "scrunch" the fabric to produce the mottling effect.

Helen, Connie, and Cat dying their fabrics at the Singaraja factory.

My batik in process at the Singaraja factory. I added a teal green after this and called it good.

Buckets of dye at the Singaraja factory. The workers put the dye in squirt bottles that we then used to dye our fabrics.

Me with a couple of piles, or maybe miles, of batiks waiting to have the wax boiled off at the Singaraja factory.

Our finished batiks laying out to dry at the Singaraja factory.

Ketut at his Denpasar factory explaining to us how the stamps are made. Denpasar is the capital and most populous city of Bali.

Stamp making artist at the Denpasar factory. He starts with a line drawing on a grid and re-creates the drawing with painstaking detail using copper mounted on a metal grid the same size and scale as the drawing.

Mounting the copper pieces on the metal grid. The artist uses only about 4 tools total to create the gorgeous stamps.

Worker boiling the wax off the batiks at the Denpasar factory.

Fabric coming out of the boiling water after the wax has been removed at the Denpasar factory.

The fabric goes straight into a water bath at the Densapar factory after the wax has been removed by the boiling process.

Fabric hanging at the Denpasar factory after the bleaching process is complete that has removed most of the initial color except what is preserved under the wax.

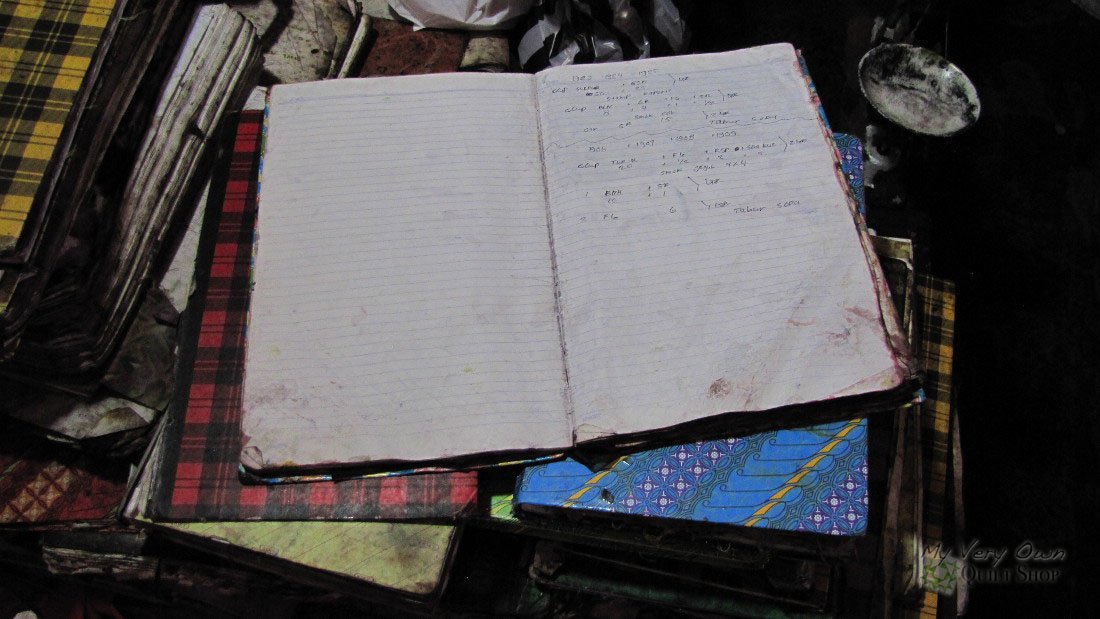

All of the color and fabric formulas are painstakingly documented in books at the Denpasar factory so that quality control can be maintained from batch to batch.

Finished fabric at the Denpasar factory that is pressed and hanging for the final drying before being wound on to bolts, which is also done by hand.

The large room full of stamps at the Denpasar factory.

Here is Scott, my husband and the other half of My Very Own Quilt Shop, just finishing up stamping his very own batik at the Denpasar factory.

And here I am stamping my batik at the Denpasar factory. Take note of the fabric color because it is going to look much different by the time it is done.

Workers performing the bleaching process at the Denpasar factory.

Scott's batik after bleaching. No more blue!

My stamped batik before bleaching.

Batiks drying at the Denpasar factory before the final rinse.

My batik after bleaching. No more purple, but because the base color was so dark, it only bleached to a mauve rather than back to white, which is always the starting base color. I think with a longer bleaching process it would have become lighter, but we had a short time frame to complete our batiks. There were other fabrics that had been left soaking in the bleach water, presumably to remove most, if not all, of the first dye color.

Ketut scrunching Scott's newly re-dyed batik.

Scott's re-dyed batik drying and waiting for the final step of removing the wax.

My re-dyed batik drying.

Soda is applied to produce the sunburst effect you see in many batiks.

Stamp under construction at the Denpasar factory.

Break time! It is very hot and humid in Bali so every day our guide, Eni (in the gold) handed out chilled and scented towels to us to cool down. Very refreshing!

The artist continuing to work on the stamp at the Denpasar factory. Stamps take from 2-3 weeks to make depending on the complexity of the design and they last about 3 years.

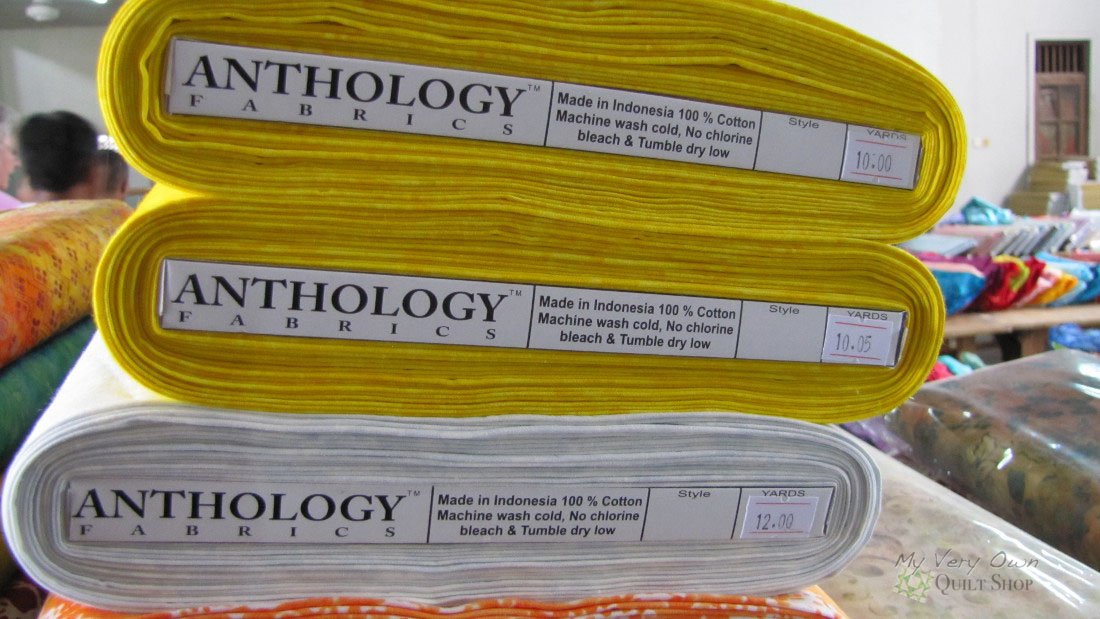

Our last stop in our batik making tour - the finishing warehouse in Denpasar. Ketut had two tables loaded with fabric for us to buy with another two tables being used to roll fabric and finish the bolts for shipping.

Two tables full of batiks being prepared for shipping to the U.S.

Gorgeous Anthology Batiks ready for wrapping and shipping to the U.S.

Me having a ball shopping in the "special" room. I found many, many treasures that came home with me . You will see that Scott caught me with my mouth open. I must have been finding a really good treasure at that moment LOL

More shopping at the finishing warehouse. Some of those piles on the end of the table are mine!

Shopping in the Textile District in Denpasar.

Batiks in the Textile District in Denpasar.

Show and Tell! Here are Connie, Marlys, Judy, Pat and me with our finished batiks that we stamped and dyed ourselves. Can you believe that my original fabric was a dark purple? All that is left of that purple is in the dolphins which is where the fabric was protected by the wax.

Scott, Pat & I with our finished batiks. Scott made his in Chicago Bears colors because he is a huge fan!